ACA has proven expertise in leak testing across industries to improve customer efficiency, accuracy, quality, and traceability.

Common Applications:

- Pressure decay/rise

- Creep/crack testing

- Chamber Testing

- Flow Testing

- Occlusion Testing

Featured Case Study

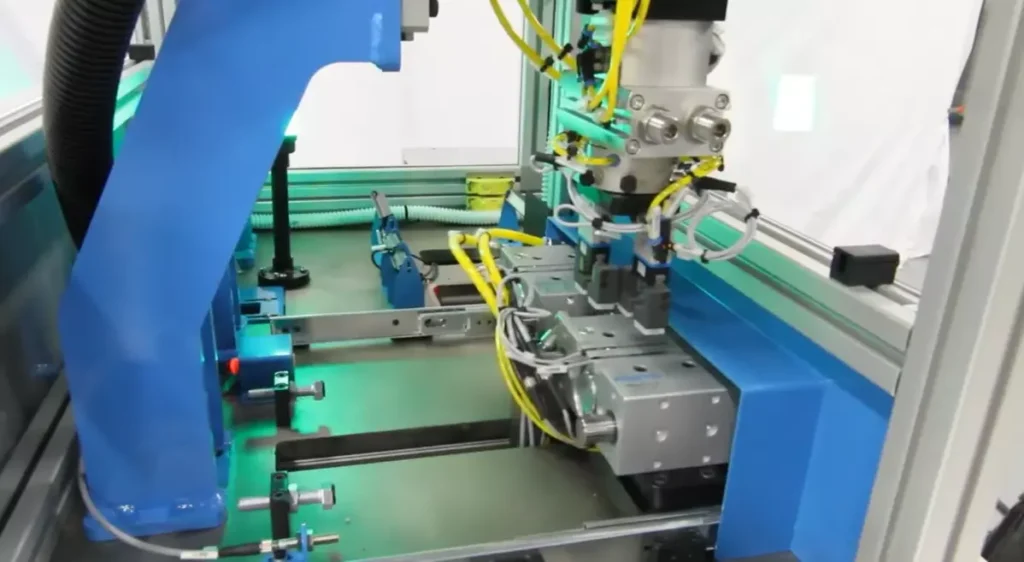

Leak Tester – Injection Molded Parts

Challenge: Build stations that test the integrity of various injection molded parts.

Solution: This piece of Leak Test Equipment consists of two identical nests to hold the parts, two leak detectors and two vibrating pin markers. The operator opens a drawer to access the part nests and load the parts. The parts nest onto a post that seals off the larger tube port. Once the operator closes the drawer, a sensor signals the machine to start. A cylinder attached to the drawer holds the drawer closed. Two additional cylinders seal off the other ports on the part. These cylinders have through holes and tubes that are connected to the two leak testers.

The leak tester performs a pressure test to check for voids, short shots, and incomplete welds. Once the parts pass inspection, the markers stamp a Julian date code on each part. The cylinders then retract, and the drawer opens allowing the operator to unload the parts and reload for the next cycle.

Video Gallery

Leak Tester for Injection Molded Parts

Let Us Solve Your Leak Testing Challenges

We view our clients not just as customers, but as valuable partners.